Series Overview

This industrial design series is a great opportunity for us to show off the design processes we go through at GSE when we're creating new hardware products. This is part 2 of a six part series that points the spotlight at our new low-cost tracking terminal, the GSatSolar. If you have not read the other articles in this series, I suggest starting with the introduction piece by clicking here, because it has important information about our processes that will be referenced throughout this article.

Part 2: Shape and Aesthetics

Of the many decisions that we kicked around, the form factor design is likely the most informed by the solution parameters. To start with, it was obvious that any design would have to be small enough to fit on a cow's ear, and light enough to stay there for up to three years. There was also a need for two flat surfaces; one for the ear, and one for the upward-facing solar panel. Given the two opposite surfaces needed to be flat, it left very little room for creative design, and rectangular solids became the default starting point for the form factor design.

The Design Process

Considering the fact that a rectangular solid was practically a given, the question became about what to do with the space between the faces, which is where spatial design intersected with functionality. Did we want a slim edge like those on a MacBook air? Perhaps a more standard flat or rounded surface that runs the entire thickness of the device would make sense. After all, this is just a rectangular solid with electronics inside... why not make it look like one?

The Goal

The goal in designing a good form factor was to be functional, but to also portray the ruggedness and durability of the device to our potential customers. This led to the conclusion that a sleek surface and slim edges would not achieve the goal of perceived toughness, as most devices with edges like that end up in protective cases. With the goal clearly in sight, it made it much easier to find the starting point for ideas.

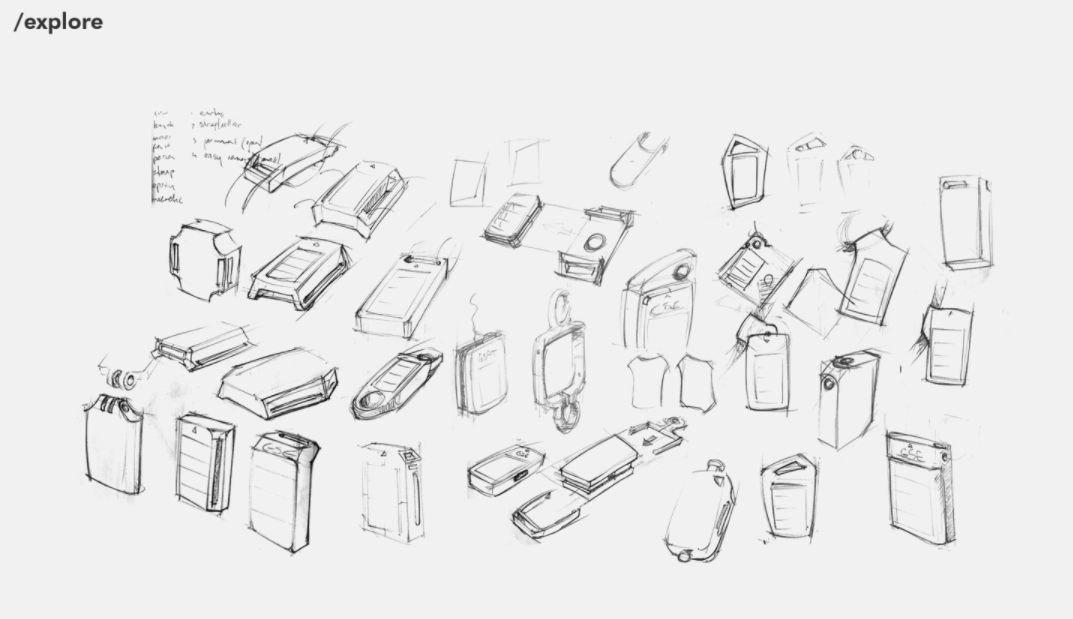

The Ideas

We based initial ideas on certain design trends in consumer product markets, pulling inspiration from various types of electronics, safety gear, adventure accessories, tools, and wearables. It was important to focus on the goal of delivering form that matched function, and as such, a large piece of the design decision process was to understand how the form factor lends itself to being mounted on the asset that would be tracked.

Narrowing Down

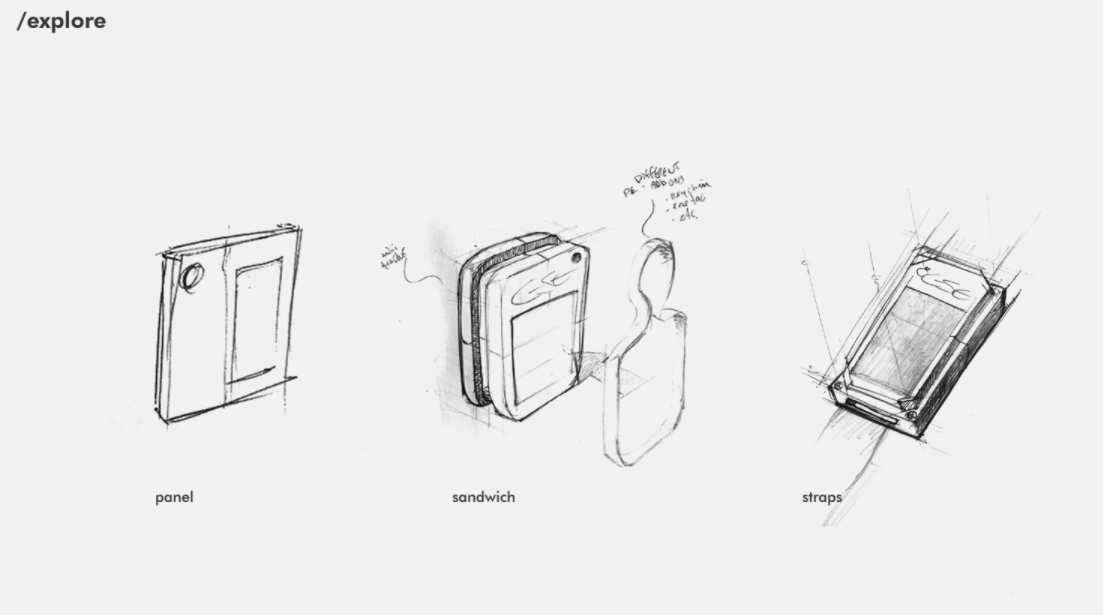

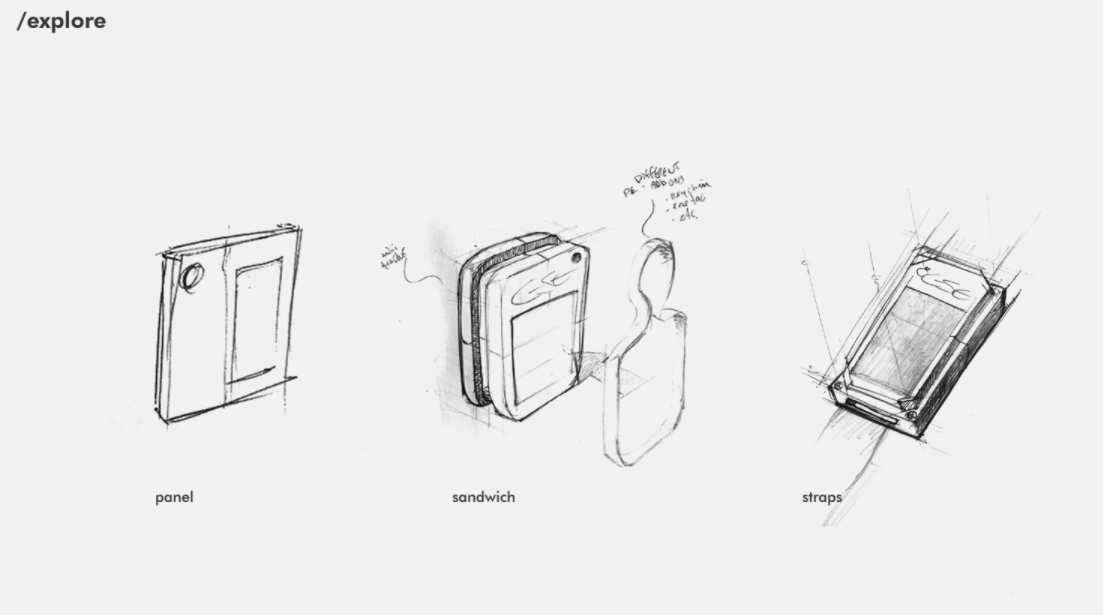

We began by identifying three main options based on a large design brief. Those options were:

- The Panel: modeled after a product many people are familiar with, the panel provides ample space for branding, and represents a familiar feeling. It also emphasizes hanging or dangling attachment mechanisms.

- The Sandwich: assumes the terminal can use its space between the front and back flat surfaces to accommodate the mounting mechanism. The value of this design is in its ability to accommodate a number of different mounting mechanisms, and the vertical stack of internal components.

- The Strap: provides the most modularity in mounting by creating bars and ridges to accommodate a strap mount, custom-designed ear mount, or clip mount.

Flesh Out

It became apparent very quickly that the leading determinant of the best design would be its ability to accommodate the largest array of mounting mechanisms. While we were designing for the ranching market and for primary use with ear tags on livestock, there are still numerous opportunities to be had in IoT and other commercial use cases. At this point, we asked to see hybridized versions of each design, trying to find the option that could satisfy the needs of as many markets as possible.

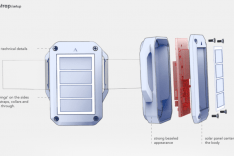

Eliminate

It became clear very quickly that the device would need to be able to maintain a relatively fixed position when installed on assets, so mounting options that were exclusively meant to have the terminal hanging were insufficient. Additionally, we determined that the best form factor would accommodate multiple mounts. Because of this, it was very easy for us to eliminate The Panel and Sandwich designs first, and focus our attention on the Strap design and how we could make it accommodate non-strap mounts.

Iterate

The Strap design was born with the idea that the tie bars provided ample opportunities to design mounting mechanisms that did not have to be part of the form factor design. This gave us the ability to focus exclusively on making decisions about the terminal's shape and aesthetics with the understanding that mounting mechanisms could be designed separately and with their own best practices applied. It was important for us to divorce these two design elements from one another so that we could focus on each being the best possible versions of themselves. This decision resulted in the creation of a hybrid form factor that had both tie bars and grooved edges to accommodate a clip.

Finalize

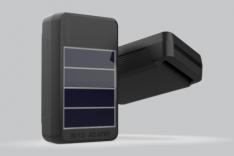

With function solved, our final decisions to make about form factor were related to the corners, edges, and flat surfaces of the unit. The final design reflects our desire to have a tough looking device (raised and beveled edges and corners), and also accomplishes our goal of delivering a compact unit. Both The Sandwich and The Strap designs pulled in the value of having a vertical stack of internal components, which is critical to delivering the smallest unit possible. This vertical stack of internal components left us with effectively zero wasted space inside the unit, giving us the opportunity to bring the size of the unit down to just over two inches on the longest side, and the final weight to just twenty-four grams.

The Outcome

The decisions that went into GSatSolar's form factor resulted in a beautifully functional design that also satisfies a number of my own personal design preferences. The first of which is modularity, as I feel an adaptable product is a fantastic starting point for new hardware. Not only can we not fully predict the ways in which this product will be used in the conceptual phases of development, we also lack the ability to predict the longitudinal needs of users. Because these devices are designed to be deployed for three full years, there's no telling what kind of intelligence will come from the first few years after the product's release. Being modular gives us the flexibility to adapt the product if our customers' needs change, and the value of that design feature is second to none.

Modularity also gives us the ability to continue engineering accessories, add-ons, and after-market products that can augment existing as well as future GSatSolar units. For example, the modular design leaves room for wireless sensor accessories to be mounted to the back of the unit, adding, for example, a temperature reading or step counter to the data collection capabilities of any unit. The simple and modular form factor lends itself to these technological augmentations in a way that building the mounting mechanism into the design would not accommodate.

More Information

The depth of the value of the modular mounting mechanisms will be addressed in part 4 of this series, but for now, suffice it to say that it was one of the most differentiable characteristics of the unit that came from the industrial design process for the form factor. As mentioned previously, there will be four more articles in this series that will bring you through our entire design process for the GSatSolar, with a focus on the major inflection points in the product's history. We encourage you to keep an eye on the blog and our social media as we bring you those articles. For more information about the GSatSolar, we invite you to read more about specs, features, and applications on the product's official website, and sign up for the newsletter as well.