GSatTrack integrates fatigue management solution to save lives and increase productivity

The US National Highway Traffic Safety Administration conservatively estimates that 100,000 police-reported crashes are the direct result of driver fatigue each year. This resulted in an estimated 1,550 deaths, 71,000 injuries, and $12.5 billion in monetary losses this year alone. Because of these statistics it’s no wonder that trucking companies around the globe are now looking into fatigue management, especially in the mining sector.

About GSatTrack

GSatTrack is a web-based, integrated satellite and GSM tracking solution, compatible with modern web browsers and works on a multilingual platform that brings together all the positions of every manufactured product under one location and displays and manages them in a single unified interface. With GSatTrack, asset locations and movements - including position, speed, altitude and heading - are tracked in real-time worldwide via GPS updates.

By using GPS satellites with the latest hardware and technology, any asset on earth, whether it's people, vehicles, containers, or any moving object can now be tracked. Our technology allows the integration of all types of tracking equipment into one easy to use platform. The tracking equipment determines its location by triangulating a position using GPS (Global Positioning System) and then transmits this information via GSM, Satellite, or VHF to a central server for processing. Any operator can view and control any number of real time assets simultaneously.

The Customer Situation

A mining company operating in the Andes Mountains needed to get its mining concentrate product transported by hundreds of trucks across 500 miles of deep mountain valleys and over passes reaching altitudes of up to 16,500 feet, surrounded by snowy peaks towering above the road in every direction, to reach the port on the Pacific coast of South America. Travelling by convoy on one way journeys of more than two days, the physical and psychological toll on drivers was immense. Slippery dirt roads with no guardrail, sometimes beside thousand foot precipices and at other times, close alongside some of the raging headwaters of the Amazon River, meant that any loss of concentration was deadly. In regular succession, the gloom of a deep river valley would give way to the bright sunshine of the Altiplano, followed by the snow, ice, fog and rain of a high pass, and then back down again into yet another deep valley. Driver fatigue and loss of alertness in the thin air was a constant problem. After several drivers had died due to fatigue induced crashes, the mining company sought to implement a fatigue management solution all along this dangerous and tiring route with the objective of zero truck incidents due to driver fatigue.

The Challenge

With cell phone coverage beyond the occasional settlements along the road generally nonexistent, a way had to be found to reliably connect the trucks to base. There were several reasons why reliable connectivity along the entire route was important. Convoys needed to stay in contact with base to report conditions along the road in real time, such as weather, accidents, landslides and mechanical problems. This was generally achieved by the use of satellite phone by the convoy leader. The mining company had worked with WOMBATT Global Pte Ltd, a company that specializes in fatigue management with 24/7 fatigue monitoring while providing data driven training to prevent fatigue in drivers before it occurred. In order to do this WOMBATT needed to know the fatigue status of each driver in real time using commercial driver fatigue detection technologies that needed to be fitted to each truck and connected to base in real time so that timely action could be taken to prevent the occurrence of fatigue related accidents. This was a problem the satellite phone could not handle.

The Solution

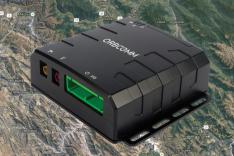

Understanding that there are pro’s and cons to every satellite provider based on coverage and offerings both Iridium and Inmarsat solutions were investigated but the device that was finally chosen for this application was the IDP-782 from Orbcomm. For this application the geostationary I-4 constellation provided by Inmarsat meant that the devices would continue to report even in the deep valleys of the mountains.

Receiving the fatigue management hardware from WOMBATT, the engineers at Global Satellite Engineering were able to discover ways of interfacing with the camera technology used for fatigue management. While video was not capable using the small data packets transferred over the IDP-782 device, pictures were transferable. The same IDP-782 device meant for monitoring driver behavior had now become a hybrid satellite and cellular solution for fatigue management without compromising any of its other features.

Once the right solution was chosen these technologies needed to be brought together in a way that gathered all the information in a single place. This was all achieved through GSatTrack. GSatTrack draws its strengths from its ability to tap into all the functionality of the devices it interacts with. GSatTrack gathered the data from the fatigue management devices and created alerts around the information. Custom reports were created through GSatTrack giving a clear view of driver behavior, vehicle maintenance and fatigue results. GSatTrack was the solution that met all the mining company’s needs and allowed them to control the information in an easy to use format that was meaningful to them.

The Result

The mining company now had a working solution that allowed the fatigue management company WOMBATT to monitor drivers’ developing fatigue in real time, taking timely intervention action to prevent accidents and increase both safety and productivity. Because the solution included the IDP-782 device, the fatigue monitoring could take place regardless of where the trucks were located using the best network connection available, whether that was satellite or cellular connectivity. With all the other features provided through the IDP-782 unit-including driver behavior and the ability to interface with a Garmin screen-WOMBATT fatigue monitors could now alert drivers of road conditions and other hazards. The mining company was now able to see how their drivers were performing in the field and even monitor maintenance schedules of their vehicles.

Over all, the solution engineered through the partnership of Global Satellite Engineering and WOMBATT Global not only protected the drivers of the mining company from harm due to fatigue, but also provided the mine with a fully monitored driver behavior service in real time that helped save lives while increasing productivity and efficiency.